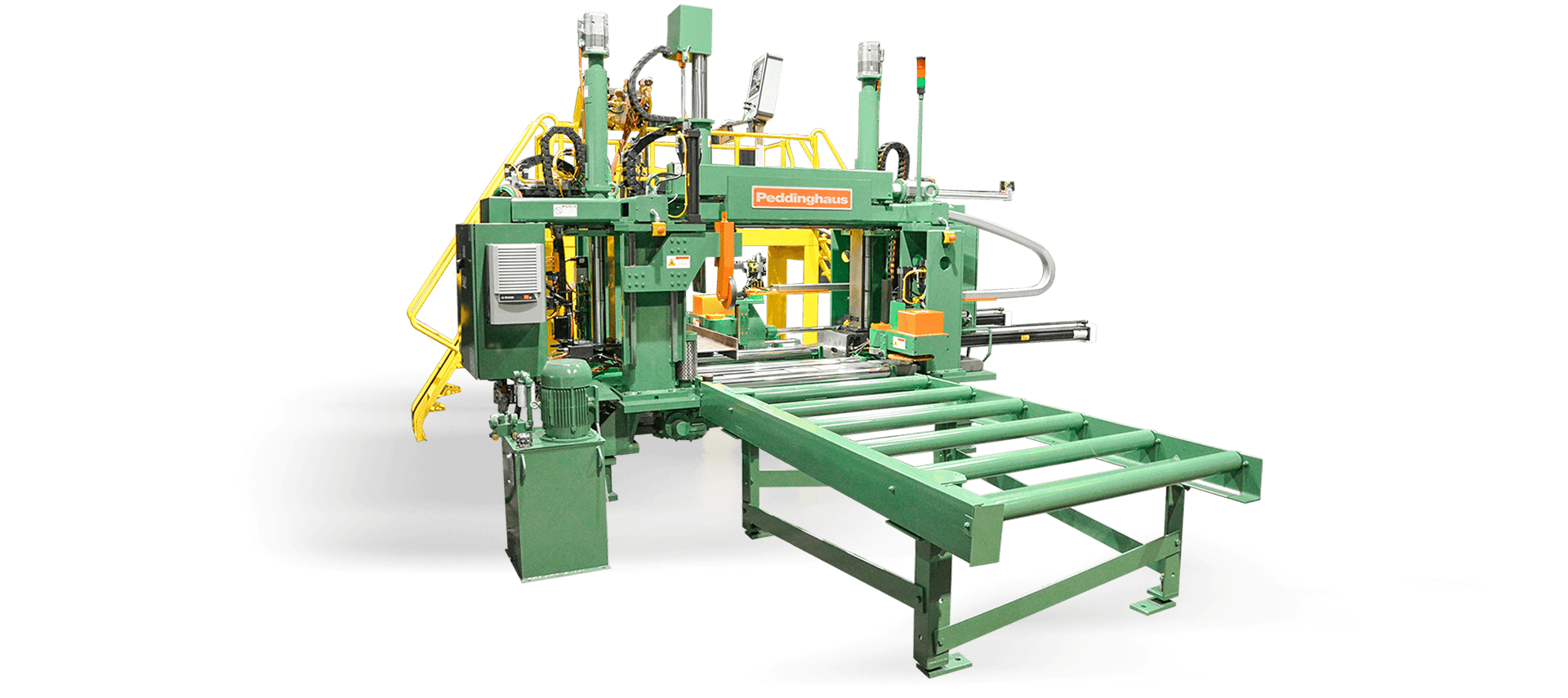

The Ideal Coping Line for Small to Medium Fabricators

The Ocean Liberator beam coping machine is proven to process steel faster and more cost-effective than manual coping methods. The Liberator is ideal for small to medium size fabricators who process block copes, flange thins, rat holes and other common copes.

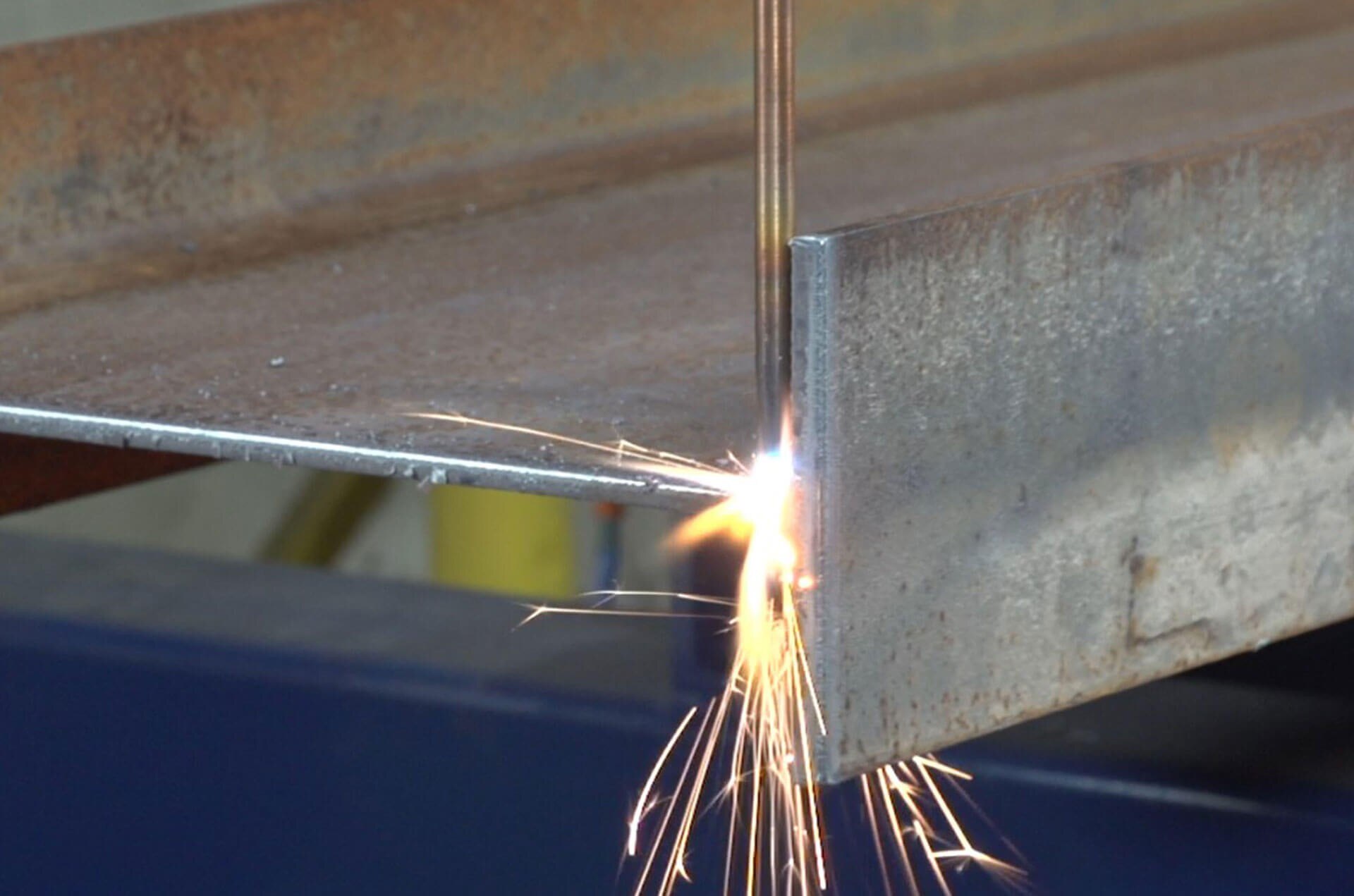

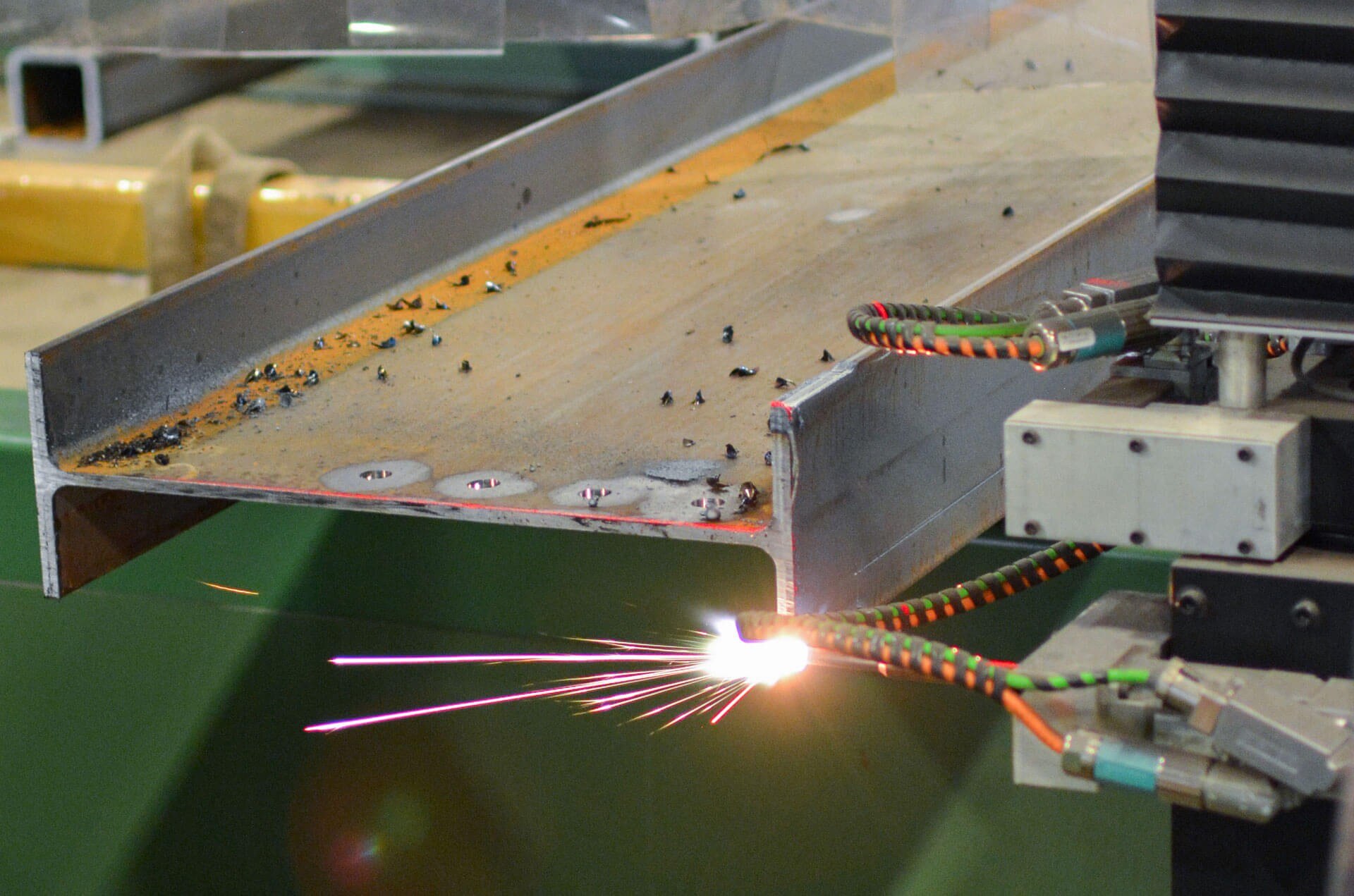

Near-Flange Oxy-Fuel Processing

Capable of miter cutting and beveled weld preparation on the top and bottom flanges, the Liberator boasts automatic torch ignition. Without the tedious torch probing processes typically associated with robotic coping machines, the Liberator allows for tighter near-flange processing.

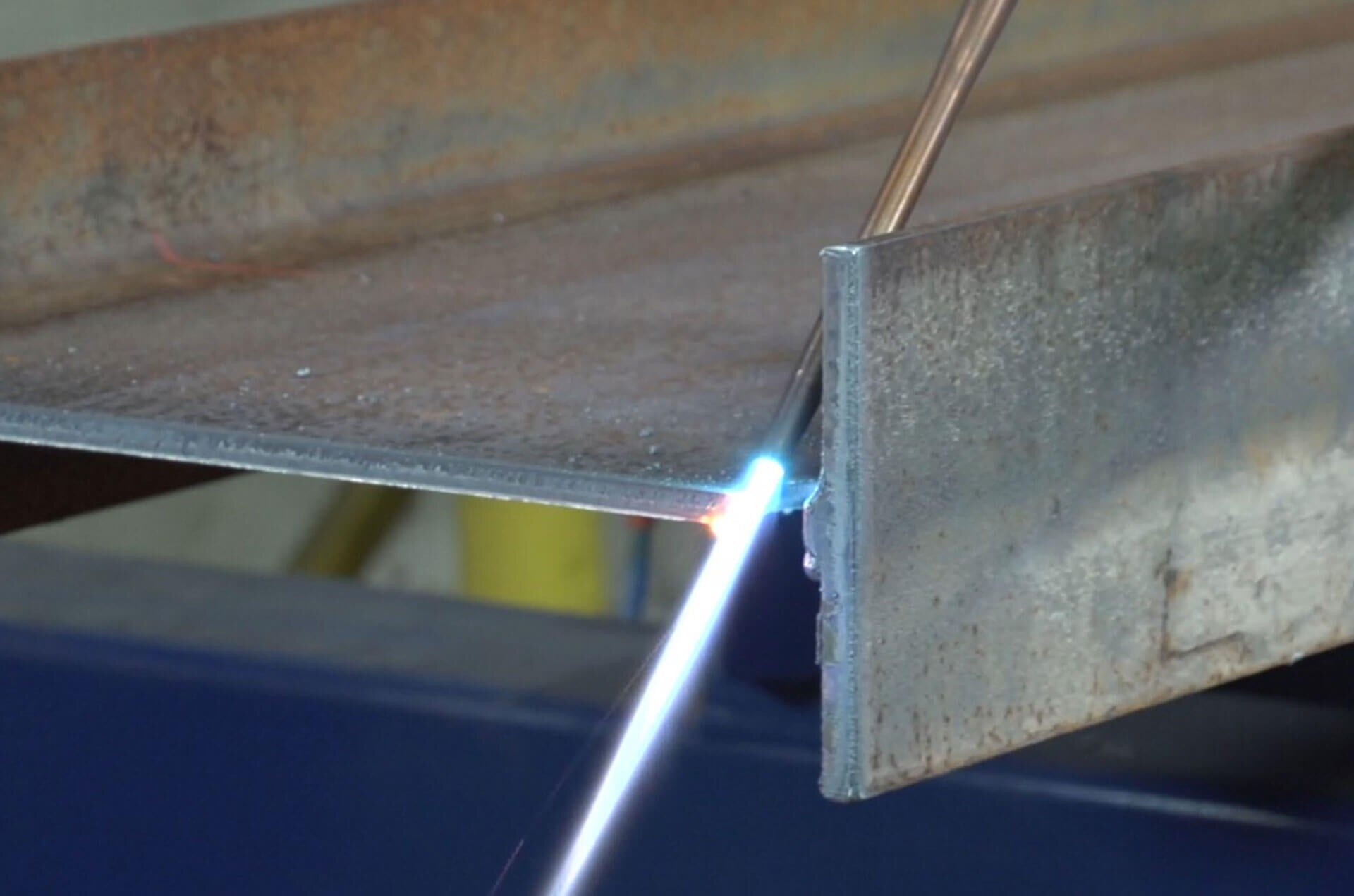

Bevel Cutting on Multiple Axes

Multiple axis positioning permits top-notch flange cutting. Flange beveling for weld prep is easily achieved with a pivoting torch to the programmed position.

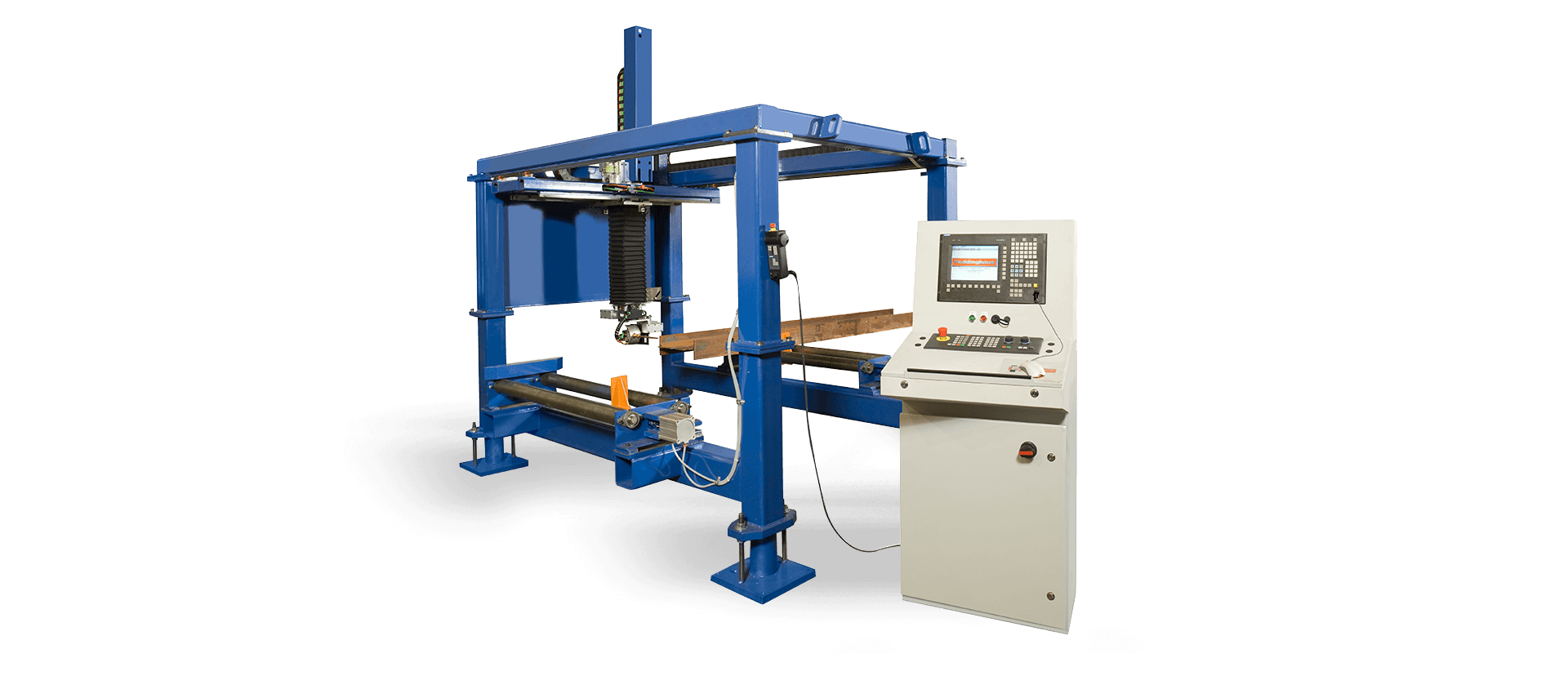

Laser Measurement and Dimensioning

Once profiles are moved into the operating area and fixed to the datum clamps by the operator, the laser beam zero reference device projects a line that enables the operator to manually jog the torch into place. From that initial measurement, the rest of the profile can be processed smoothly.

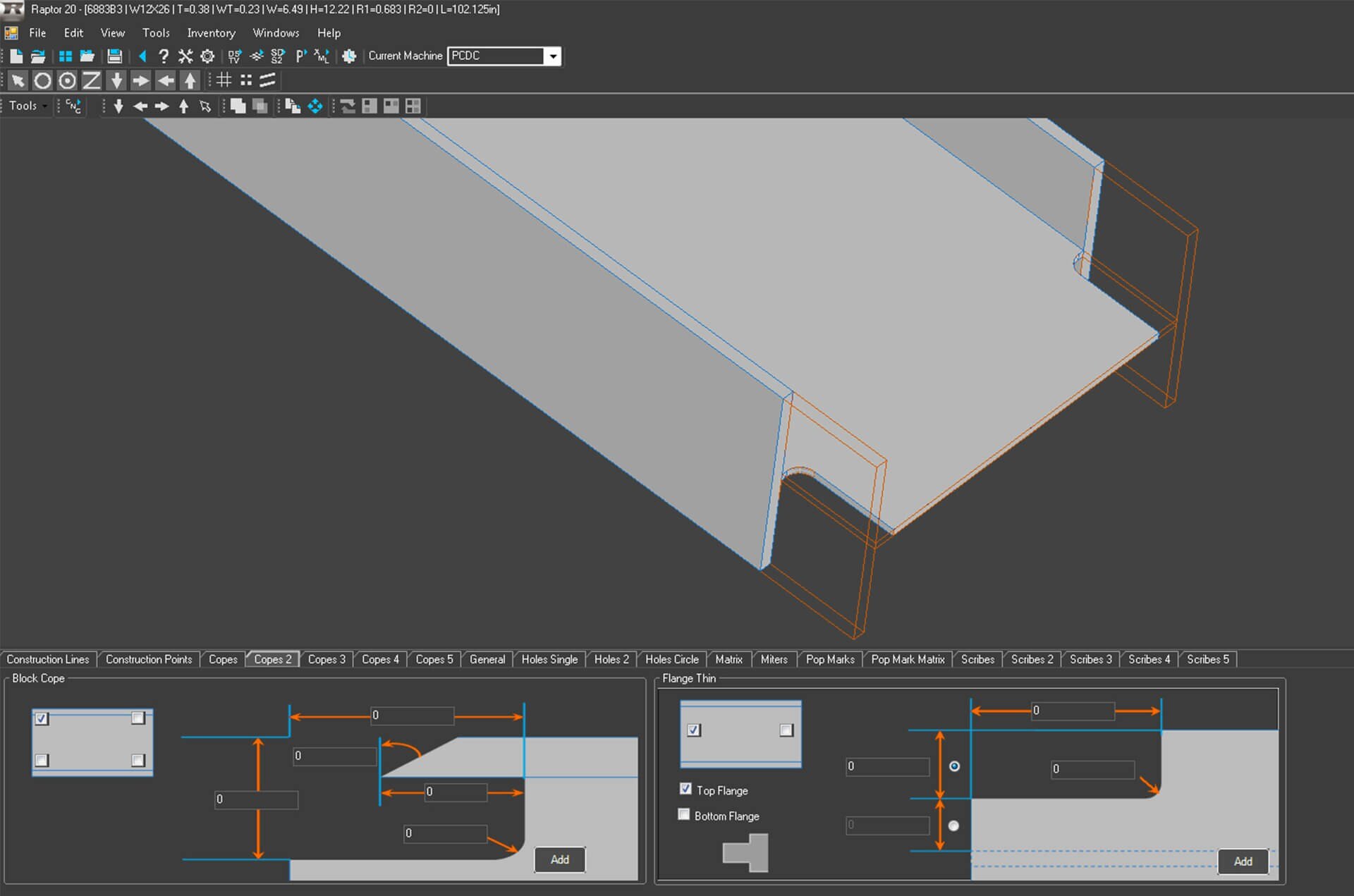

Raptor 3D CAD/CAM Software

Developed by Peddinghaus, Raptor 3D CAD/CAM Software takes CNC innovation further by enabling users to program faster and more accurately. Inspect, modify and export part information directly within the 3D platform. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators.

The Ideal Coping Line for Small to Medium Fabricators

The Ocean Liberator beam coping machine is proven to process steel faster and more cost-effective than manual coping methods. The Liberator is ideal for small to medium size fabricators who process block copes, flange thins, rat holes and other common copes.

Near-Flange Oxy-Fuel Processing

Capable of miter cutting and beveled weld preparation on the top and bottom flanges, the Liberator boasts automatic torch ignition. Without the tedious torch probing processes typically associated with robotic coping machines, the Liberator allows for tighter near-flange processing.

Bevel Cutting on Multiple Axes

Multiple axis positioning permits top-notch flange cutting. Flange beveling for weld prep is easily achieved with a pivoting torch to the programmed position.

Laser Measurement and Dimensioning

Once profiles are moved into the operating area and fixed to the datum clamps by the operator, the laser beam zero reference device projects a line that enables the operator to manually jog the torch into place. From that initial measurement, the rest of the profile can be processed smoothly.