Overview

- Thermal Cutting/Coping Line

- Robotic Plasma Cutting

- Roller Feed Measurement

- Camera System

- Integrated Layout Marking

- Profile Length Detection

- Bevel Cutting

- Fanuc Robot Arm

- Grind Reduction Technology

- Hypertherm XPR 300

- Modular Control

Plasma Cut

Pierce Up To

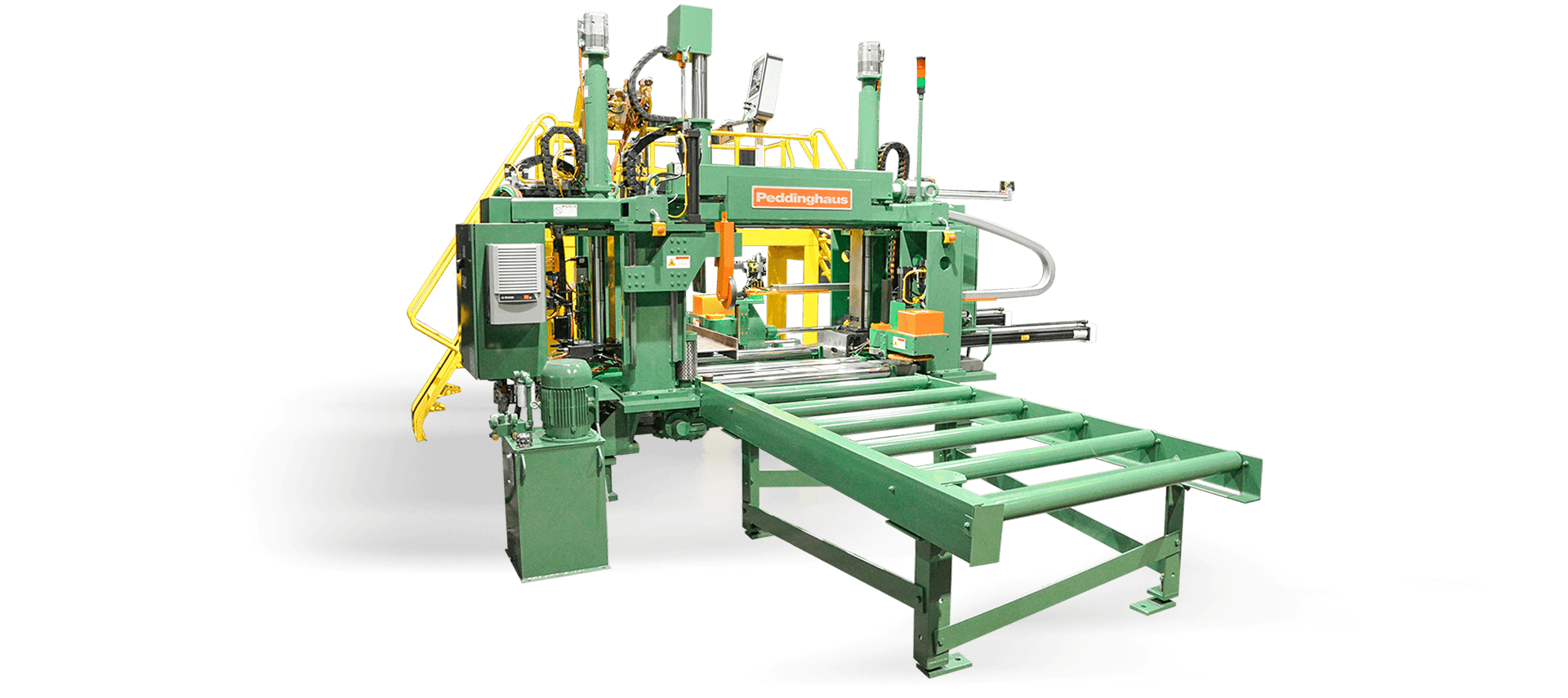

High Capacity Processing for Steel

Designed to revolutionize your beam cutting production, this advanced technology takes innovation further with a camera system that measures deviations in material and then adapts the robot’s cutting path for perfect fitting - no probing necessary.

Maximize Profile Accuracy

Specialized torch movements throughout production on the PeddiBot-1250ST robotic CNC beam coper practically eliminate the need for grinding. That equals labor savings and more profit in your pocket.

Robotic Plasma Cutting

The PeddiBot-1250ST robotic CNC beam coper comes equipped with a Hypertherm XPR 300 (300 amp) plasma cutting system. The XPR 300 is designed to combine faster cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity.

Camera System

The PeddiBot-1250ST is equipped with a camera system consisting of five main cameras that measure material in the processing zone to generate precise cut paths for the torch. An additional camera is dedicated to trail end processing, capturing measurements as the material moves into the machine. This system is significantly faster than laser or touch probing machines.

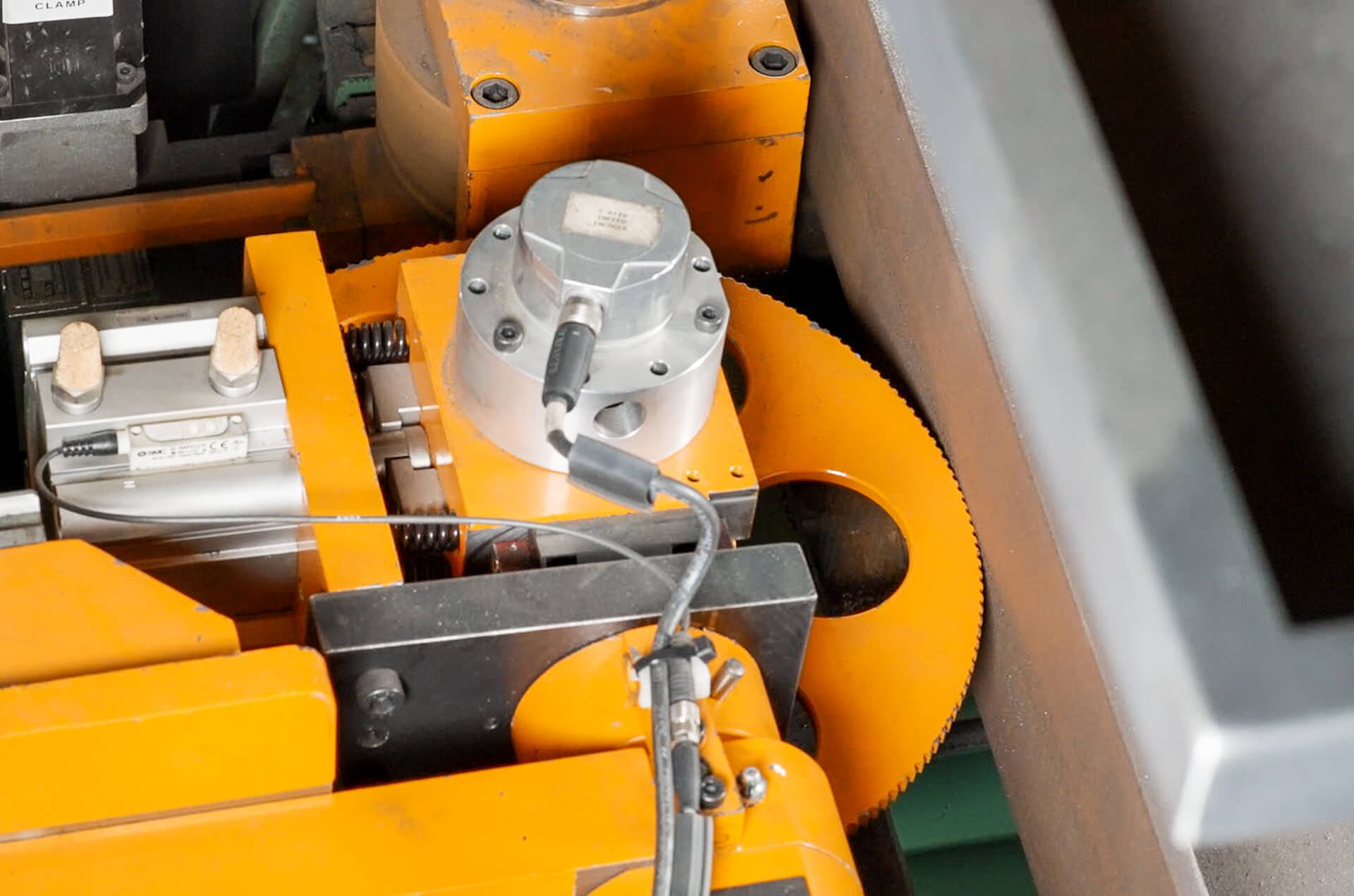

Peddinghaus Roller Feed Measuring Wheel

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

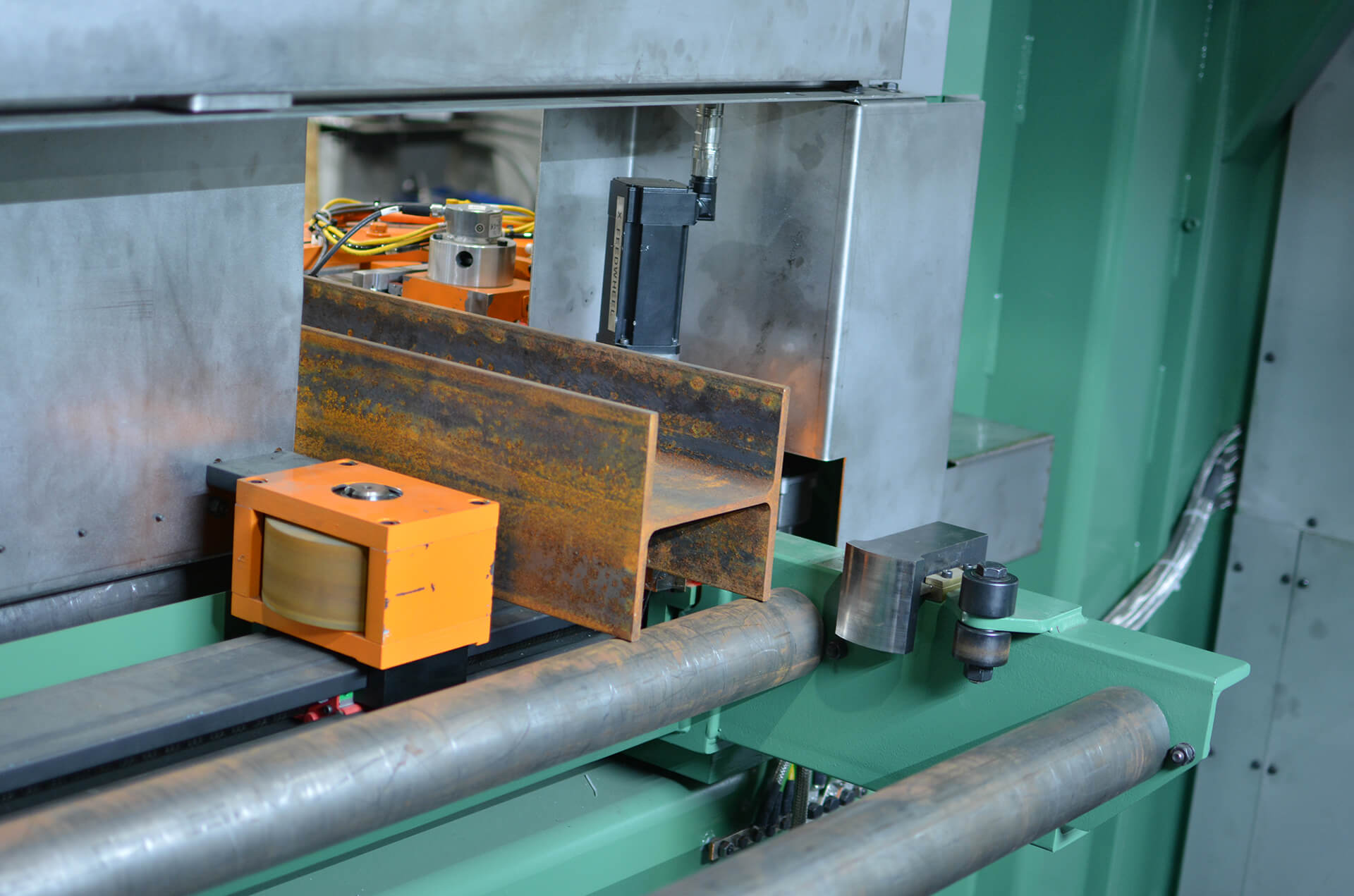

Sturdy Material Clamping

The PeddiBot-1250ST uses all-electric conveyors while a polymer drive roller works seamlessly with the conveyors for smooth material handling. With a fully electric design, it eliminates the need for hydraulics, using a precise electric actuator for horizontal clamping.

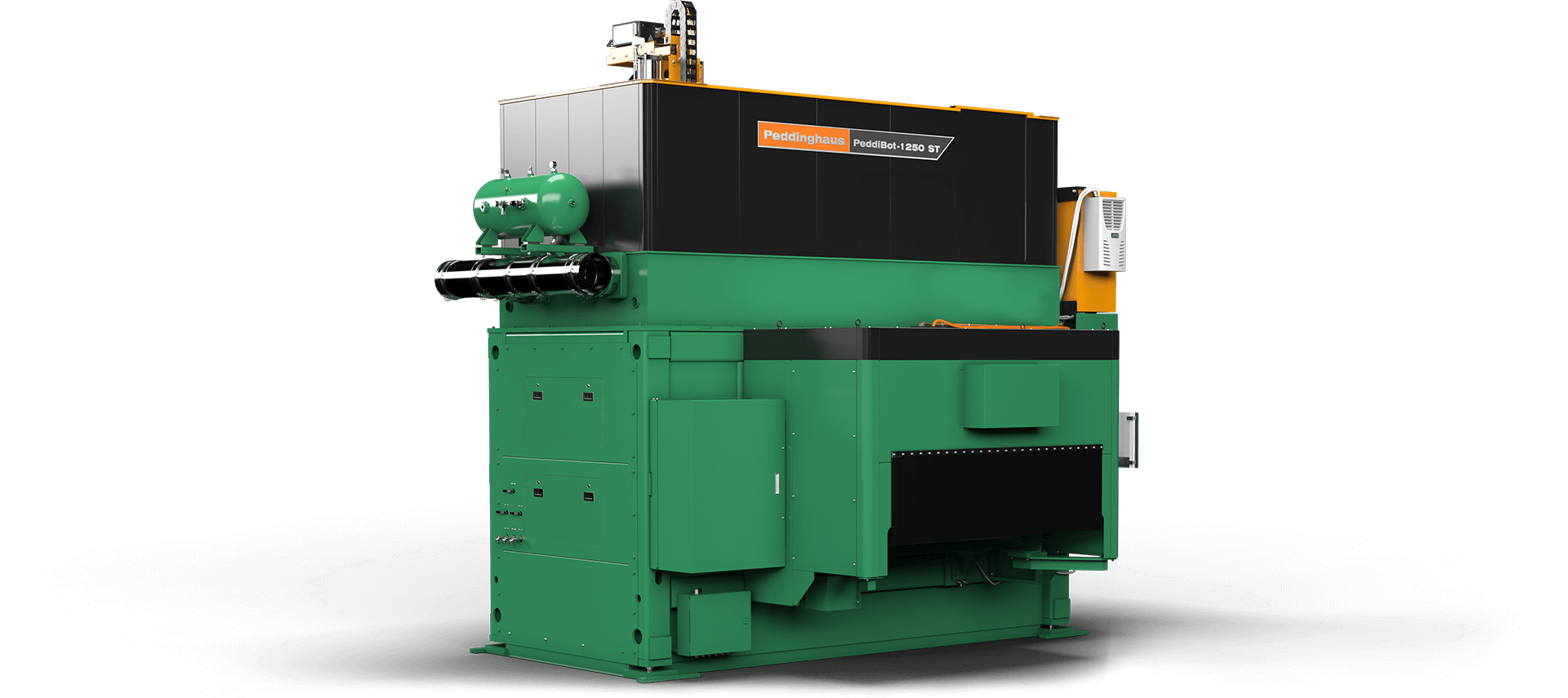

Compact Design

The compact design features a smaller arm than other robotic thermal cutting machines, making it more nimble and enabling faster processing. Its smaller footprint allows it to fit into more shop environments, maximizing versatility and efficiency.

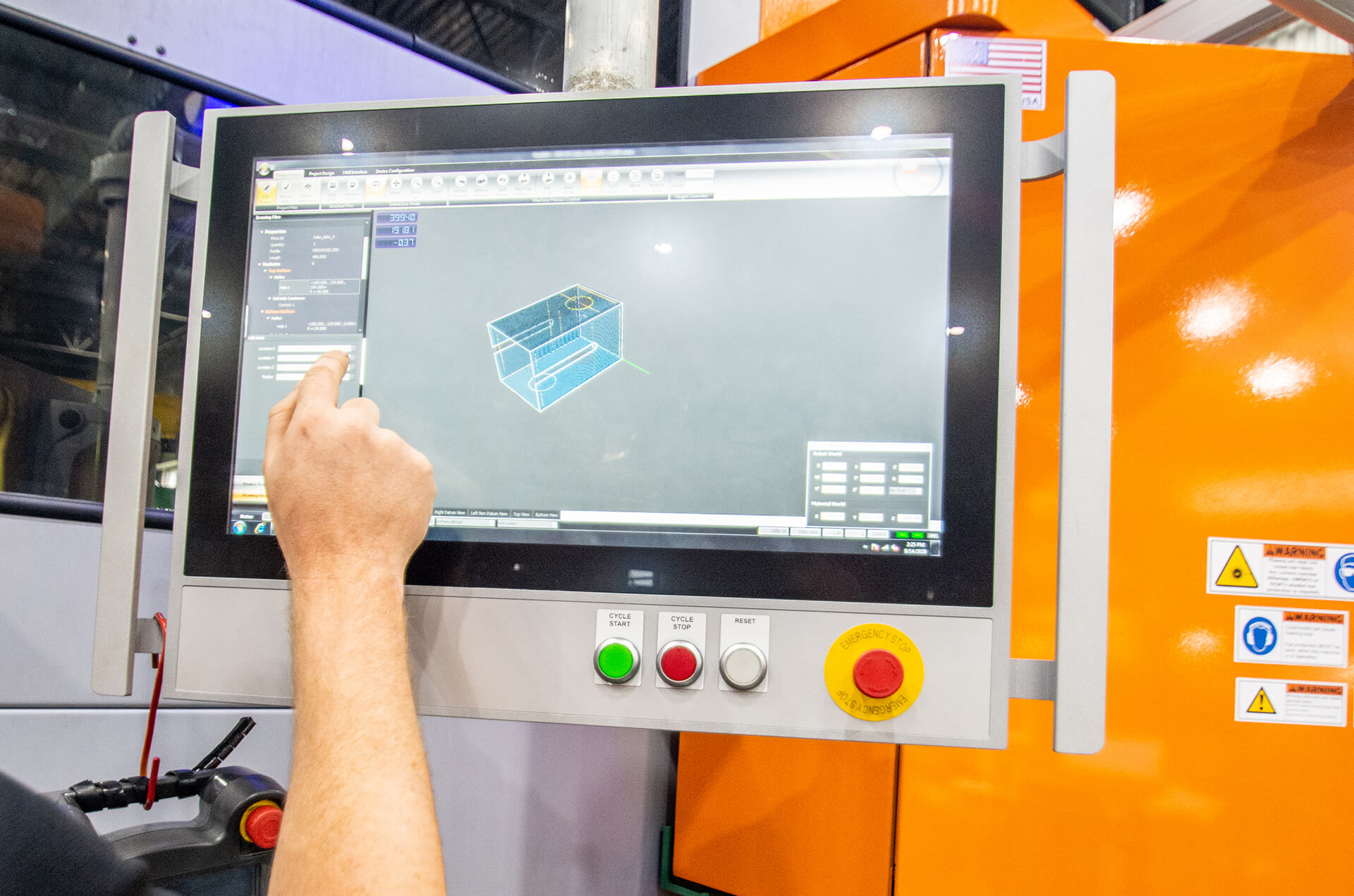

PeddiBot-1250 Advanced Software

Developed by Peddinghaus, this platform executes features for robotic tool path creation in multiple project environments. The advanced software accepts industry-standard DSTV files and is compatible with Raptor 3D CAD/CAM Software by Peddinghaus. Once material has been scanned, a real-time 3D point cloud is displayed for easy monitoring of each piece being processed.

High Capacity Processing for Steel

Designed to revolutionize your beam cutting production, this advanced technology takes innovation further with a camera system that measures deviations in material and then adapts the robot’s cutting path for perfect fitting - no probing necessary.

Maximize Profile Accuracy

Specialized torch movements throughout production on the PeddiBot-1250ST robotic CNC beam coper practically eliminate the need for grinding. That equals labor savings and more profit in your pocket.

Robotic Plasma Cutting

The PeddiBot-1250ST robotic CNC beam coper comes equipped with a Hypertherm XPR 300 (300 amp) plasma cutting system. The XPR 300 is designed to combine faster cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity.

Camera System

The PeddiBot-1250ST is equipped with a camera system consisting of five main cameras that measure material in the processing zone to generate precise cut paths for the torch. An additional camera is dedicated to trail end processing, capturing measurements as the material moves into the machine. This system is significantly faster than laser or touch probing machines.

Peddinghaus Roller Feed Measuring Wheel

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

Sturdy Material Clamping

The PeddiBot-1250ST uses all-electric conveyors while a polymer drive roller works seamlessly with the conveyors for smooth material handling. With a fully electric design, it eliminates the need for hydraulics, using a precise electric actuator for horizontal clamping.

Compact Design

The compact design features a smaller arm than other robotic thermal cutting machines, making it more nimble and enabling faster processing. Its smaller footprint allows it to fit into more shop environments, maximizing versatility and efficiency.